The dreams of many science fiction writers like Philip K.Dick and Neal Stephenson are getting closer to becoming reality. 3D printing is closing the gap between prototyping as a very exclusive and expensive manufacturing method and just making. Earlier this year I wrote about the RepRap that makes prototyping more affordable. Some of the most recent endeavors in prototyping show that it's possible to hack, crack and rethink the equipment one needs to prototype, what materials prototyping comes in and what purposes it serves.

Behrokh Khoshnevis developed a concept to 3D print houses out of concrete on architectural scale. Already in 2005 actually, but I only discovered lately, he calls his machine a contour crafter. It would be able to print a house in just 24H. If that comes to live it will revolutionize the construction industry in many ways. First of all it will make house-building much cheaper, secondly it will create much less waste that the traditional construction methods do today.

|

| via Inhabitat |

|

| via Inhabitat |

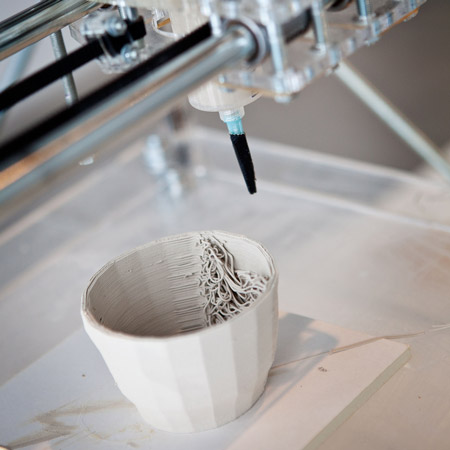

During this years designweek in Milan, Tim Knapen and Unfold where showing an experiment. A virtual pottery-wheel that the spectators could use to craft a vase out of thin air. They where literally waving with their hands at a laser-projection to shape a vase. The hand-movements where being tracked with motion-tracking software, and all the vases created being saved in the computer. The last 16 created being projected on the wall. Every now and then a creation would be printed with a 3D clay printer (modified RepRap). Again this turns the creation and manufacturing process upside down. The spectator becomes a participant in the creation process, and even if he cannot make pottery at all, he can still create one of these vases. Also the visual language that goes with these vases is different. The wireframe that CAM software uses to build the vase creates traces in the clay-print. It creates a new type of facets.

|

| via creativeapplications.net |

|

| via designboom.com |

But what maybe impressed me most was the Endless chair-printer robot devised by Dirk van der Kooij, on show during the Dutch Designweek in the new lifestyle shop by PietHein Eek.

Dirk has imported an old robot from China and reprogrammed it into a 3D printer, it takes polymer granulate and injects that into a 3D form, by exhausting a continuous (endless) string of hot polymer, that gets stacked on-top of itself, and eventually forms a chair. This new system of production breaks with the idea of mass-production because it is not constrained to a mold, every chair can be different to the previous one. each production loop can be used to test and improve previous types. The robot can also be used for up-cycling end-of-life consumer products, by re-using their plastic waste.

These are great signals of change, change that will be impactful in many ways. Production, distribution and consumption will be turned up-side down once these methods develop into consumer friendly propositions. There is still some way to go, and this may all seem quite experimental, but once when the raw edges get sanded off then our system will change. People will first have to become aware that they can have a high level of influence on their new products, and then they will have to step into the creation and production process to participate. I'm sure in the beginning many will feel slightly uncomfortable doing this, but soon it will be normal. And don't we hear all the time, that people are craving to customize and personalize. I'm sure they will learn quick.

And then we can all live the Philip K.Dick and Neal Stephenson dreams.

No comments:

Post a Comment